Cold Chain Shipping Keeps Drugs Safe in the Summer Months

Mail order is a popular way for patients to receive compounded drugs, especially now that many speciality and compounding pharmacies developed shipping solutions during the pandemic. Medications must be kept within a specific temperature range in order to keep them safe and effective. If medications become too hot during shipping, they can lose efficacy and may need to be replaced by the provider. Specialty and compounding pharmacies can avoid this by using validated shipping containers, as recommended by USP protocols.

Validated shipping containers

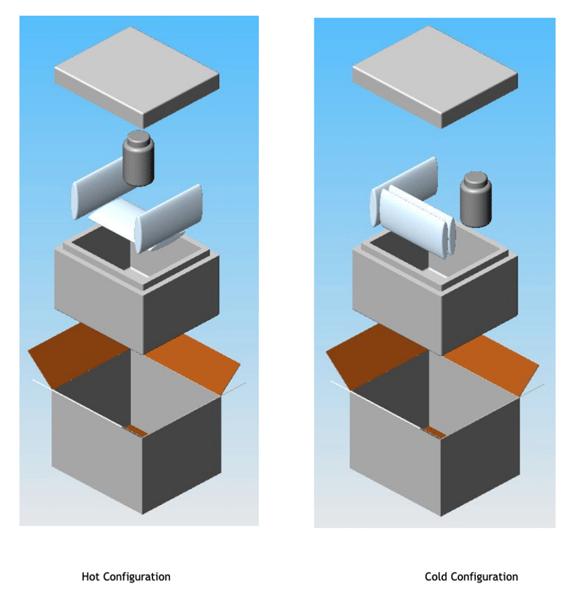

Shipping container validation ensures package integrity, guaranteeing that shipments of drugs arrive to the customer within the specified temperature range. Cold chain containers are designed to maintain internal drug temperatures between 2-8° C throughout the shipment’s duration. Shipments of refrigerated and room temperature drugs that become too cold or too hot during transportation lose potency or efficacy, resulting in an economic loss for the pharmacy. During the summer months, and in warm climates, frozen gel packs are used to prevent drugs from freezing.

Shipping container validation ensures package integrity, guaranteeing that shipments of drugs arrive to the customer within the specified temperature range. Cold Chain containers are designed to maintain internal drug temperatures between 2-8° C throughout the shipment’s duration. Shipments of refrigerated and room temperature drugs that become too cold or too hot during transportation lose potency or efficacy, resulting in an economic loss for the pharmacy. In wintertime or cold-weather environments, keeping drugs from freezing requires use of non-frozen gel packs in the container. These gel packs to absorb the cold so the drug does not crystalize. In summer and warm climates, frozen gel packs are used to prevent drugs from freezing.

Shipping container validation procedures

The International Safe Transit Association (ISTA) developed test procedures and testing standards for the proper qualification of insulated shipping containers. According ISTA, the shipping standards ensure packages are survivable, sustainable, and successful. ISTA also provides lab certifications for physical and thermal testing of insulated shipping containers. These certifications allow pharmacy buyers to purchase pre-qualified products. Alternatively, package buyers may choose to perform their own in-house evaluations to validate shipping containers.

Additional factors to be considered for container validation include compression, shock, vibration, temperature, humidity and pressure testing.

Suppliers can assist pharmacies with cooler validation in two ways: by setting up customers directly with pre-validated insulated packaging companies and testing laboratories, or by assisting with in-house shipping container studies, from concept to execution.

For an internal study, whereby companies ship their own products to known route and customer destinations to create their time/temperature data, pharmacy suppliers can provide customers with standard operating procedures, the equipment required to perform internal studies (including data loggers, temperature probes and temperature indicators), and process the resulting data. Based on the drug(s) being shipped and ambient temperatures of the shipping and receiving destinations, suppliers will then recommend package sizing, inner packaging materials including dunnage and insulation, and gel pack sizes for testing. They can also modify the shipping configuration based on the resulting shipping test data.

Our recommendation for safe shipping

At DiNovo, we only recommend products that we trust will do the right job for our customers’ specific needs. By recommending the right products, our customers are able to decrease costs and grow their business.

The right products are not always the most expensive, or the cheapest. For example, few pharmacy shipments require 4-inch thick, 96-hour rated shipping containers, as the less costly 1.5-inch thick, 48-hour rated containers provide more than adequate survivability and sustainability.

We recommend pharmacies consider extending shipping validations from 24 to 48 hours. The extended validation time reduces total shipping cost by as much as half and provides a time buffer for delivery should unexpected delays occur during transportation via commercial carrier.

For more information on how we can help with your shipping needs, please give us a call today!

About DiNovo

Since 2013, DiNovo Cleanroom Supplies and Packaging Solutions has been a leader in delivering cleanroom consumables, disinfectants, medical devices, and cold chain shipping solutions to the compounding and specialty pharmacy marketplace. As an educational resource, coupled with top global manufacturer partnerships, DiNovo is able to help pharmacies drive efficiency, manage costs, and enhance compliance to help guide you through a constantly changing pharmacy marketplace.

.png?width=500&height=153&name=DiNovo%20Full%20Logo%20-%20Both%20Tags%20(500x153).png)